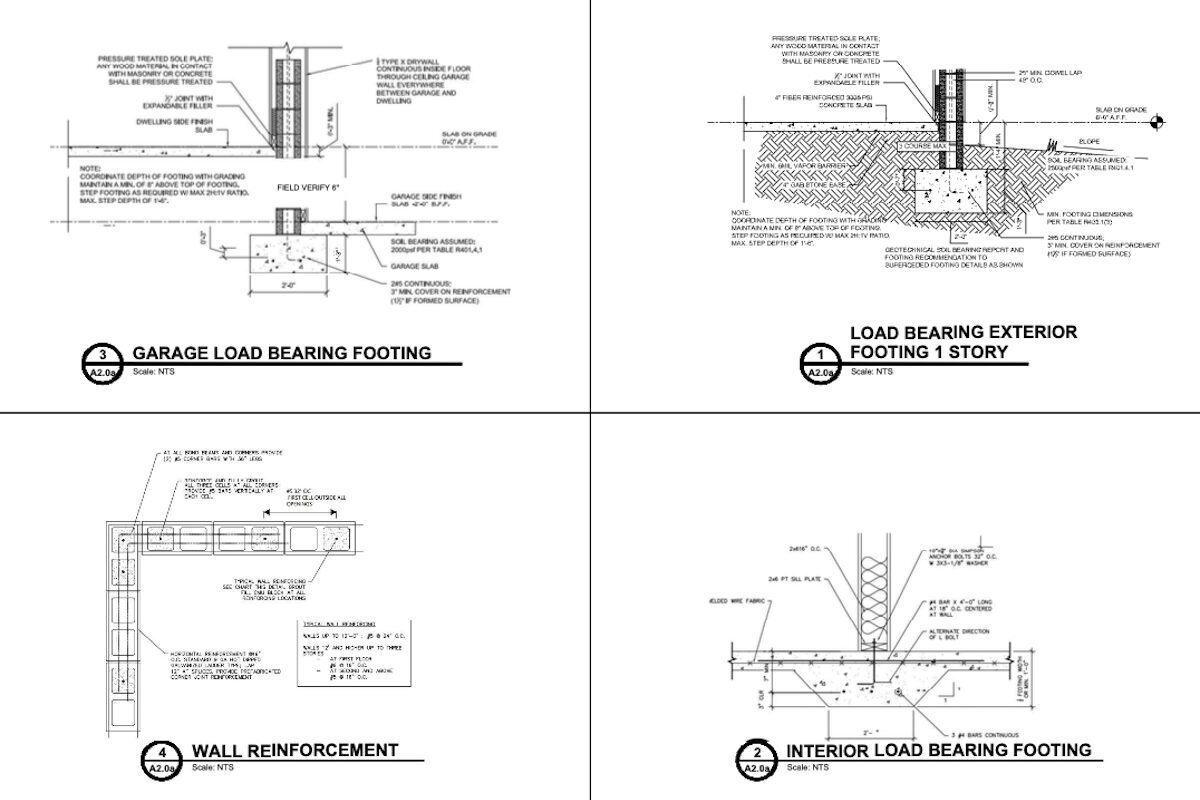

First in our monthly home construction series—October 2024 Hello, financial freedom lovers! If you're new here, I'm José, and along with Tatiana, I write about our FIRE journey. Today marks the beginning of an exciting new chapter in our story—one that I hope will inspire, inform, and maybe even save you some money along the way. Every first Wednesday of the month, we'll be documenting our adventure of building our dream home from the ground up. But this isn't just another home construction blog. As FIRE enthusiasts who achieved early retirement through careful planning and investment, we're approaching this build with the same analytical mindset that helped us reach financial independence. We'll share every cost, decision, and l

José

José concluded his distinguished 13-year career at Vanguard at age 44, stepping away from corporate life to embrace an early retirement. As a project manager, he expertly orchestrated the creation and delivery of educational materials—both digital and print—for 401(k) participants, ensuring resources reached millions of investors. Today, he embraces life's simpler pleasures: quality time with family, pursuit of passion projects, discovery of new adventures, and leisurely meals in his garden oasis.

View all posts by José →You might also like

0 0 votes

Article Rating

Subscribe

Login

0 Comments

Newest

Oldest Most Voted

Inline Feedbacks

View all comments